Development Trends of Rubber Injection Molding Machine Equipment

2021-01-15(2783)Views

The rubber injection machine concept was proposed in the mid-1940s; in the early 1970s, rubber cold feed injection began to be practically applied in industry. Because it can achieve high temperature rapid vulcanization, the rubber material is preheated and plasticized before entering the mold cavity, and the product is molded and cured in a sealed high-pressure mold cavity. The product quality is uniform and stable, the size is accurate, and fully automatic operation can be realized. Compared with the method, the production efficiency can be increased by more than ten times, so the technology of producing molded products with rubber cold feed injection machines has been increasingly widely used.

Rubber injection molding machines are mainly used in the production of auto parts, industrial parts, electrical insulation parts, connector sockets, seals, shock absorbers, shock covers, shoes, bottle plugs, vacuum hoses, sheaths, valve pads, toys And fitness equipment. With the development of the automobile industry, the quality requirements for seals, electrical connectors, shock absorbers, etc. are getting higher and higher. The demand for rubber injection has increased by more than 12,000 times. The strong market demand is the development of rubber injection machines. Provided an opportunity.

At present, the major international manufacturers of rubber injection machines are: REP company in France, MAPLAN company in Austria, WP company in Germany, STEINL company and DESMA, Matsuda Manufacturing Co., Ltd., Kobe Machinery Co., Ltd., Sanyou Co., Ltd., Japan Steel Works , Italy RUTIL company and so on.

In the early 1970s, Beijing University of Chemical Technology cooperated with a factory in Shanghai to successfully develop the XZL-200 screw pre-plastic one-line rubber injection molding vulcanizing machine. China has introduced a large number of rubber injection machines from Europe, America, Japan and other countries. On this basis, domestic manufacturers such as Huatai, Huacheng, and Huaye (now known as Qianpu) have also begun to develop and produce rubber injection machines.

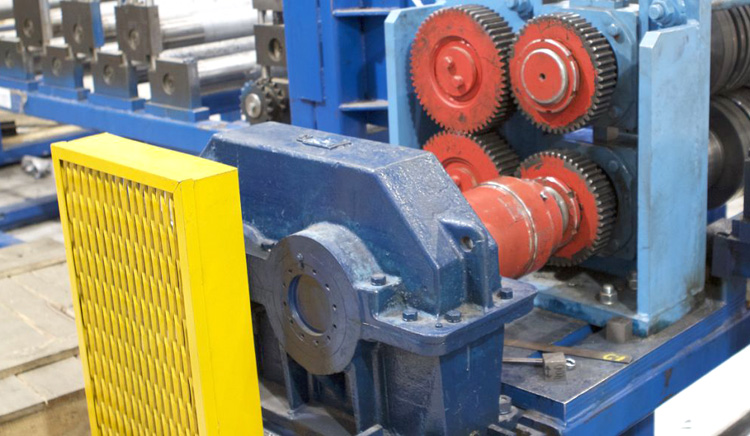

Rubber injection molding machine structure type

There are many types of rubber injection molding machines. So far, rubber injection molding has gone through 3 stages: plunger injection, screw reciprocating injection and screw-plunger injection.

plunger injection molding machine

At the beginning, rubber injection molding used a plunger injection molding machine. The injection molding method is: after the rubber is fed into the barrel from the feeding port, the rubber is heated and plasticized by the heater outside the barrel. , So that the rubber material reaches a temperature that is easy to inject without scorching. The plunger injects the plasticized rubber into the mold under high pressure. In fact, this injection method barrel mainly plays the role of injection, supplemented by heating and plasticizing. Because rubber is a poor conductor of heat, the heat transfer efficiency is low.

If the rubber is heated only by heat conduction, the temperature of the rubber rises too slowly and the plasticization is uneven. Therefore, it is necessary to heat the rubber material in a heat mixer first, and then feed it into the injection machine after being heated to a certain extent. Therefore, although this injection molding method has a simple structure and low cost, it needs to be equipped with a heat mixer and rubber mixing workers, which increases equipment costs and labor intensity. The important thing is that this injection molding method has low production efficiency and low cost. The chemical is not uniform, which affects the quality of the product.

Latest News

-

Precision Rubber Preformer Rubber Filter

The computer version of the precision pre-forming machine is...

-

4 points of attention when rubber injection molding machine extruder

People should not be in front of the mold before the plastic...

-

Kesheng rubber molding machine: advantages of rubber injection molding machine

It simplifies the process of producing rubber molded product...

-

Functional advantages of liquid silicone feeder

With the needs of the ever-changing industrial development, ...

0769-38955228

Hotline:0769-38955228

Phone:13826937784

Fax:0769-38955226

Email:webmaster@szksma.com

Address:Dalai Management District, Huangjiang Town, Dongguan City, Guangdong Province

13826937784

13826937784